West End Collegiate Church and Collegiate School traces its origins to the 1628 Reformed Protestant Dutch Church, when New York was still New Amsterdam. As such, it was appropriately designed in the Flemish Renaissance style and was completed in 1893.

The building was deemed a NYC landmark in 1966 and was added to the National Register of Historic Places in 1980.

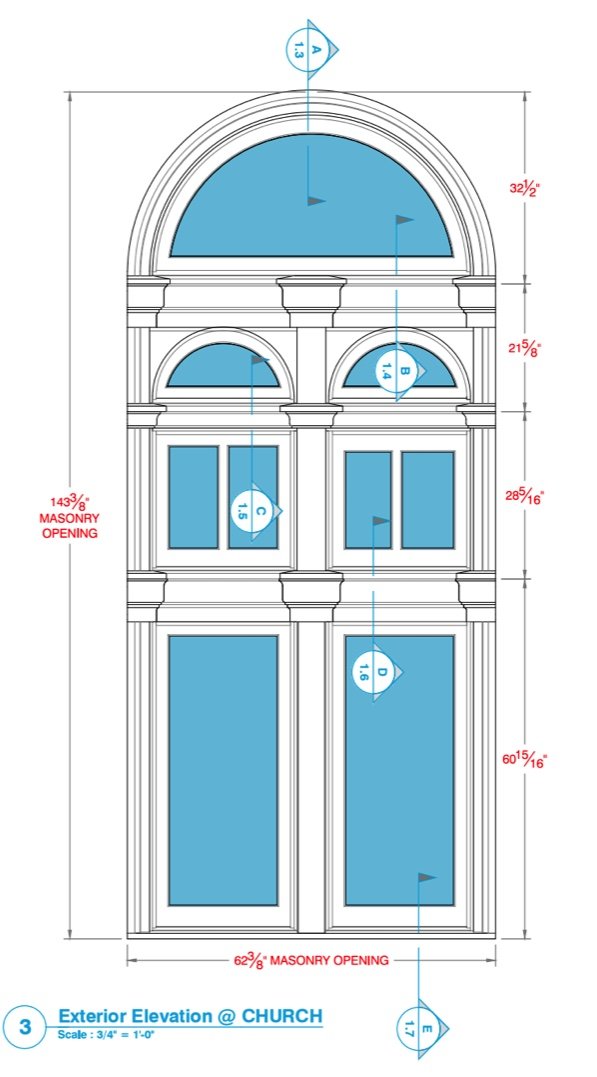

Right Path was tasked with the replication of six windows in the church. They were about 20’ off of the floor, and were five feet wide and thirteen feet tall.The windows were comprised of four sections, of which the top two sections had arch top details and were fabricated using all mahogany.

One of the reasons mahogany was chosen for this project is that it machines easily and well, with very little tear out if done correctly. These windows required meticulous hand crafting in order to replicate every last detail, and also to satisfy the rigorous requirements of NYC Landmarks.

Before fabrication could begin, we took precise measurements and made templates from the existing windows to ensure exact duplication.

Then the modern jointers and shapers began recreating what had originally been done with hand tools. This traditional side of carpentry is the hallmark of true craftsmanship.

The large arched top transom was a true semi-circular radius. It was created by bending 1/4” solid mahogany veneers over the plywood template.

A wide strap was used to manipulate the veneers into an arch, which were then clamped into place.

The same procedure was used on the two smaller arched transoms which were just above the four fixed units.

All of these components were then joined together by horizontal mullions.

The measurements had to be precise in order the receive the stained glass salvaged from the original windows. It was of the utmost of importance these windows were exact copies for that reason.

When the original windows were removed, great care was taken in applying protection to the church interior, as well as trying to keep dust down to the bare minimum.

The windows were installed from the interior of the church.

The scaffolding system was 30’ tall and was a narrow version in order to fit into the transept where the windows were located.

As part of the installation process, a pulley system was employed to hoist the windows up to their positions once the blocking, waterproofing, and metal panning had been applied.

With the windows in place, brickmolding was then applied to the exterior of the windows. They were then caulked and the painting was touched up to complete the process.

All of the work had to be coordinated around when church services were being held. Not one single service was cancelled due to our work.